Moncalieri plant

Torino Distillati headquarters are located in a historical Art nouveau-style building while the production facilities date back to the 20th century. A new productive unit is located in Santena, only a few minutes away from the Turin ring.

The Plants shows how the attention for details is the basis of the quality of distillates, gin, brandy, grappa, rum and liqueurs produced there.

- Area: 14,406 sq.m.

- Covered area: 8,643 sq.m.

- Covered area (3 story building): 12,000 mq.

- Tanks capacity: 1,500,000 litres

- Potential bottling capacity: up to 10,000,000 bottles per year

- Mean daily capacity: 1,000-6,000 bottles per hour

Santena plant

The Santena plant, previously used exclusively as a storage facility for finished products and dry materials, and the ageing of Brandy, has been renovated to become a second production unit. There is a bottling line with an output of 4,ooo bottles per hour already operating in an area of about 2,000 square meters, with the possibility of adding another one. In addition, numerous stainless steel tanks with the related equipments have been installed for the production of liquids (with possible refrigeration). It means an important added value offering customers greater flexibility in production capacity and an additional guarantee of risk balancing in the event of business interruption.

The Santena plant, previously used exclusively as a storage facility for finished products and dry materials, and the ageing of Brandy, has been renovated to become a second production unit. There is a bottling line with an output of 4,ooo bottles per hour already operating in an area of about 2,000 square meters, with the possibility of adding another one. In addition, numerous stainless steel tanks with the related equipments have been installed for the production of liquids (with possible refrigeration). It means an important added value offering customers greater flexibility in production capacity and an additional guarantee of risk balancing in the event of business interruption.

- Area: 76,000 sq.m.

- Covered area: 6,000 sq.m (beyond keeper’s house, canteen and offices for about 1,000 sq.m.)

- Potential bottling capacity: up to 6,000,000 bottles per year

- Mean daily capacity: 4,000 bottles per hour

- Sprinkler system

The need to implement an ecological transition towards more sustainable production systems has led to the installation of a photovoltaic system which also involves a significant reduction in Co2 production and electricity costs. The power of 120 kilowatts is sufficient to supply electricity to all current users.

The industrial area, although of previous construction, falls within the perimeter of a SIC area (Site of Community Interest) established to protect an amphibious species which is a priority at community level: the common Spadetoad (Pelobates fuscus insubricus). It is a tiny toad at risk of extinction living in small and isolated populations in the Po-Veneto plain and present in the Red List as “EN” (endangered); consequently the possible expansion of further industrial buildings in the area, decreed by the current PEC (agreed executive plan) is subject to rigorous compliance to the implementation of compensation works to mitigate negative impacts. That also includes the realization of environments suitable to the reproduction and permanence of this species in particular, but with beneficial effects throughout the natural ecosystem of the area.

The industrial area, although of previous construction, falls within the perimeter of a SIC area (Site of Community Interest) established to protect an amphibious species which is a priority at community level: the common Spadetoad (Pelobates fuscus insubricus). It is a tiny toad at risk of extinction living in small and isolated populations in the Po-Veneto plain and present in the Red List as “EN” (endangered); consequently the possible expansion of further industrial buildings in the area, decreed by the current PEC (agreed executive plan) is subject to rigorous compliance to the implementation of compensation works to mitigate negative impacts. That also includes the realization of environments suitable to the reproduction and permanence of this species in particular, but with beneficial effects throughout the natural ecosystem of the area.

The approved PEC would allow the construction of warehouses up to 9,000 m2. Furthermore, the purchase of a land adjacent to the current property is at an advanced stage of negotiations and further warehouses up to 2,500 m2 could be built.

First rate distillates, rum, brandy and grappa

Production and bottling of alcoholic beverages and syrups are the excellence of the company: due to modern technologies Torino Distillati can meet almost any production request; it has systems for making infusions, natural extracts, for distillation of gin and other distillates, refrigeration (also flash-chilling) and for the stabilization of distillates, brandy and grappa.

Bottling lines versatility is the main feature: 8 bottling lines at Moncalieri, 4 for mignon bottles only and 1 at Santena, offer a wide choice and can be tailored to different sizes and shapes (up to a hundred), for both cork caps, heat-shrunk caps, screw caps and GPI caps.

Some lines allow the production of very complex packaging that is normally not achievable with high-volumes lines.

Versatility and efficiency: productive capacity varies from 1,000 to 6,000 bottles per hour. Also dense products can be bottled due to a volumetric filling machine (working even PET bottles).

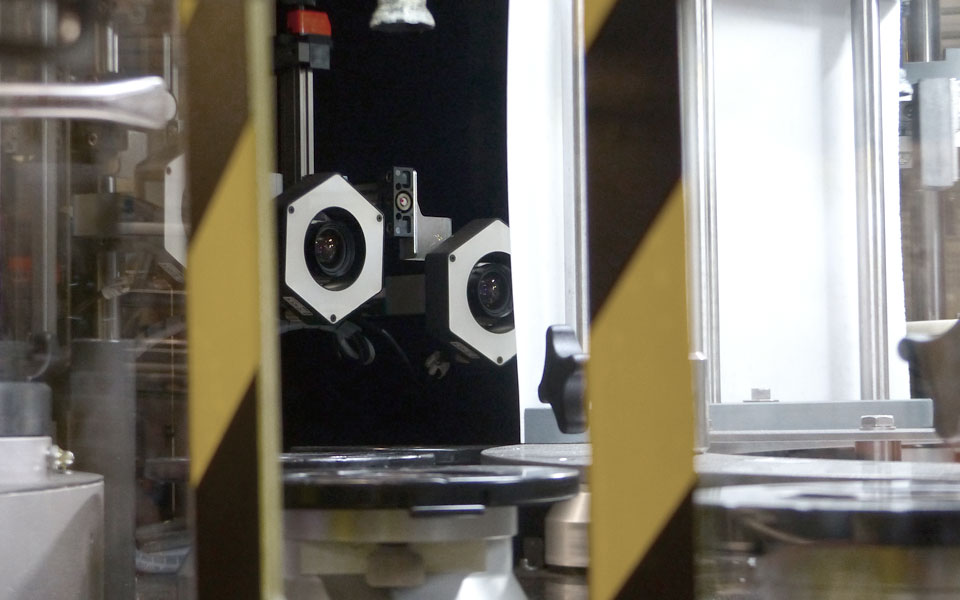

There are highly computerized modular labellers allowing a perfect dressing on non-standard products. They have a camera for the centering of bottles and a Quality Control station for putting aside defective bottles automatically.

CONTROL AND LICENCES

The whole production plant operates as a Fiscal warehouse with excise tax suspended under the control of the local Customs and Excise which also has supervision of the subsidiary warehouse for Government stripstamps located inside the factory. Torino Distillati holds licences also for producing and bottling intermediate products such as Vermouth, and for bottling fruit vinegars. A warehouse is only dedicated to the production of personalized and promotional packaging for alcoholic beverages and already bottled beers.